What’s Wood Briquette Machine

Wood briquette machine refers to the equipment for making rectangular or hexagonal logs as fuel from biomass materials, such as sawdust, rice husk, bamboo, wood chips, etc. Materials for making briquettes are required <5mm in size and <12% moisture. So the accessory equipment wood crusher and sawdust dryer usually are needed.

Sawdust Briquettes Forming Principle

Biomass briquettes forming relies on two chemical substances, lignin and cellulose. Large amounts of lignin and cellulose exist in the wood materials.

Lignin has no melting point but it has softening point. When the temperature comes to 180 ℃, lignin begins to soften and plasticize. At this time, continue heating the temperature to around 340℃, and apply a certain pressure, lignin will stick to cellulose and bind with adjacent particles.

Wood Briquettes Forming Conditions

The best humidity of biomass materials for making briquettes

The moisture content of biomass materials has a great impact on the briquetting process and briquette quality.

When the moisture is too high, there will be a lot of steam generated during heating. Steam gathering together in the center hole of wood briquettes, it is easy to causes the crack briquettes.

Meanwhile, if the materials are too dry, it is also difficult to produce briquettes. Because the trace moisture can promote the lignin softening and plasticizing.

What’s the temperature for producing sawdust briquettes

Briquetting temperature has a great influence on the wood briquet’s production speed, density, appearance, and quality. Therefore, the appropriate temperature must be adjusted for different raw materials. Hardwood materials, it is usually around 350℃.

Low temperatures can not soften the lignin in the raw material, which will cause the molding cylinder to be blocked and difficult to produce briquettes. Excessive temperature will cause the surface layer of the briquettes carbonized, which makes the materials hard to form. Even if it can be formed, the density of the briquette is not enough. If the carbonization is severe, a carbonized layer is formed on the inner wall of the molding cover, which will make the briquettes hard to discharge out.

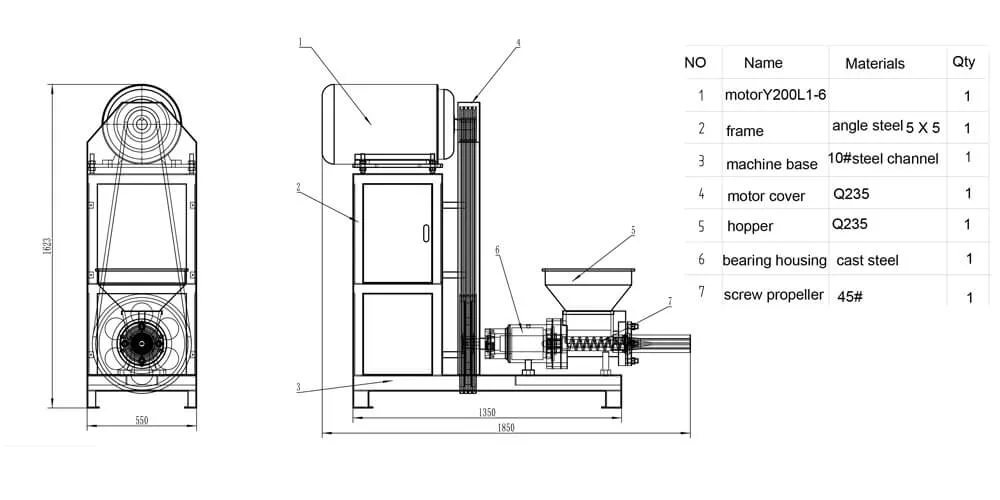

Wood Briquette Machine Design

Operating procedures of wood briquette machine

- Tighten all bolts.

- Check all lubricating parts.

- Check power voltage and electric current to see if they are normal.

- Start and run the wood briquette machine for 30 minutes without load. If there is no abnormal phenomenon such as blocked or bump, machine can be used directly.

- Set the temperature to the demanded temperature. Only when the temperature reaches the fixed point, operator begins to feed the materials.

- At the beginning, feed small amount materials, gradually increase feeding amount until the qualified product is produced. Normal working for 30 minutes indicates the test is successful, then the briquettes machine can enter normal production.

- Before stopping the machine, empty the materials feeding hopper, and run it reversely for one minute to make the material in propeller come out.

Cautions in producing wood briquettes

- Before starting the machine, turn the belt pulley manually to see if it is blocked.

- Tighten the bolts on the heating tube, esp, the three withstanding screws.

- Before stopping the machine after continuous work, empty the hopper first, and run it reversely for one minute, then the machine can be stopped.

- When the screw propeller can’t rotate, stop the briquettes machine at once, run it reversely, clear the material in the hopper, and raise temperature again.

- Briquettes discharging direction is better pointed to a wall and a plank should be put in front of it against wall.

- When the wood briquettes machine is working, the person is forbidden to stand in front of the outlet.

- Electric circuit should be kept dry and clean, power must be turned off after stopping the machine.

- Stone and iron chips are strictly forbidden to get into the feeding hopper. As soon as any abnormal phenomenon appears, stop the machine at once.

- All lubricating parts must be oiled every two months.

- It is forbidden to start the machine without the machine being well grounded.