Customers who use charcoal briquette extruder machine for more than half a year may encounter similar problems:

If your machine also experiences these problems, then you should check if the vulnerable parts of the machine are worn out, and then replace the spare parts, so that the machine can resume normal operation.

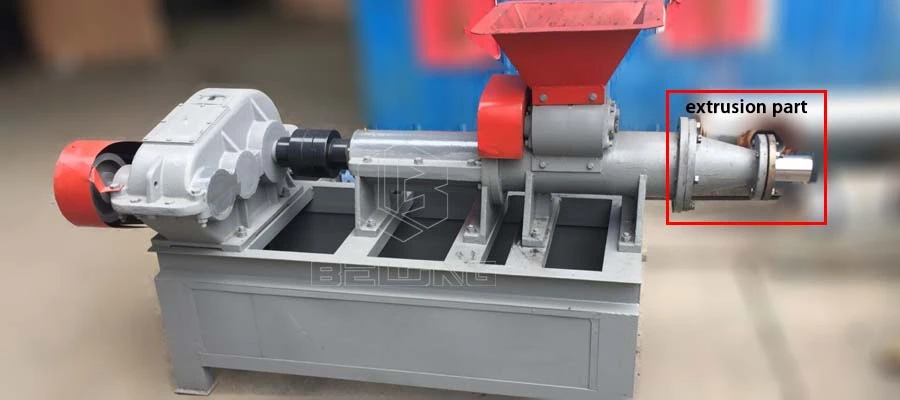

The structure of the charcoal briquette extruder machine is not complex. Simply put, it is driven by a motor to rotate the spiral shaft to transport the mixed charcoal powder to the mold for extrusion molding. From its design structure and working principle, it is not difficult to know that the part with the highest friction is the extrusion part.

The extrusion part contains three accessories: a conical discharge tube, a head screw propeller, and a mold. They are the main spare parts for the charcoal briquette extruder machine.

If there is a slow discharge after about half a year of operation of the charcoal briquette extruder machine, it is necessary to check whether the head screw propeller and conical discharge tube are worn.

There are 6 grooves inside the conical discharge tube. If the groove is ground flat, it needs to be repaired or replaced with a new conical discharge tube.

The method of repair is to use a tool to deepen the groove a bit.

If the spiral front end is severely worn, it can be repaired with wear-resistant welding rods or replaced with a new one.

The service life of the mold is longer. In general, if the shape and diameter of the produced charcoal briquettes are not affected, there is no need to replace the mold, unless different shapes of charcoal briquettes are to be produced.