The charcoal briquette machine, also known as the coal powder briquette machine, is a screw extruder machine that compresses the material into briquettes of a specific shape and size.

It can be used to manufacture barbecue (BBQ) charcoal, home heating charcoal, activated carbon, etc. The finished charcoal briquette is smokeless and odorless, has high heat value, and can endure burning for a long time.

Raw Material

The charcoal briquette machine uses excellent anthracite coal or charcoal powder as raw materials, and adopts advanced technologies such as carbonization, activation and appropriate adhesive to process the raw materials into hollow or solid briquettes.

If the raw material is biomass material, such as coconut shell, wood shavings, rice husk, peanut shell and bamboo, it should be first carbonized by a carbonization furnace, and then crushed into charcoal powder by a charcoal crusher machine, and then pressed into charcoal briquettes by this charcoal briquette extruder machine.

Coal powder or charcoal powder before entering this charcoal briquette machine should meet the requirements below:

Size: less than 3mm

Moisture: around 20%

Finished Products

Charcoal briquettes are usually made from compressed charcoal dust, which comes from sawdust, wood chips, or coconut shells. They are commonly used for outdoor grilling and barbecuing because they burn hotter and longer than traditional charcoal. They also produce less smoke and ash, making them a cleaner fuel option.

Coal briquettes are usually made from coal dust and other additives, such as starch or clay. They are commonly used for heating and cooking in industrial settings, such as power plants or steel mills. They burn hotter and longer than traditional coal, and they produce less smoke and ash.

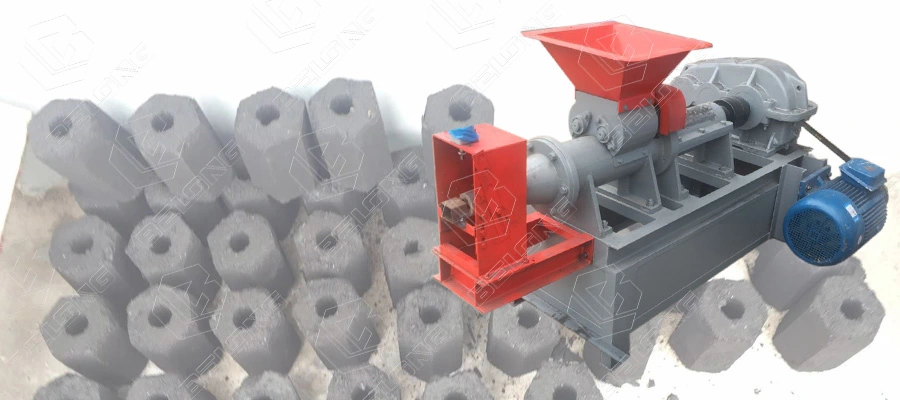

Briquette Molds

The molds of charcoal briquette machines come in various shapes (see the picture below) and sizes, depending on the specific requirements of the briquette to be produced. Some common shapes include cylindrical, square, and hexagonal. And the diameter range of final briquettes is 3 to 5cm.

Technical Parameter

| Model | Power | Capacity | Briquette diameter | Machine size | Machine weight |

|---|---|---|---|---|---|

| 140 | 11kW | 300-400 kg/h | 3-5cm | 2*1*1.1m | 700kg |

| 180 | 18.5kW | 800-1000 kg/h | 3-5cm | 2.2*1.2*1.2m | 1200kg |

At Which Step in the Charcoal Production Line Is the Charcoal Briquette Machine Used: STEP 4

Step 1: Carbonize the raw material with a carbonization furnace

Step 2: Crush the carbonized material with a professional charcoal grinder

Step 3: Mix the powdery material with a charcoal mixer

STEP 4: Compress the mixed material to charcoal briquettes with a charcoal briquette extruder machine

How The Charcoal Briquette Machine Works

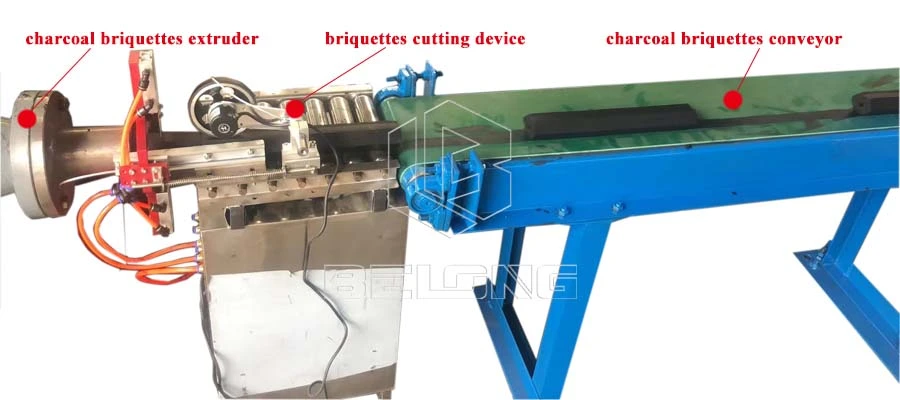

Cutting Auxiliary Equipment

If you have requirements for the size of the finished charcoal briquettes, you can consider purchasing an additional auxiliary cutting equipment. Set the size you need, and the long charcoal rods coming out of the charcoal extruder machine will be cut into exactly the same size charcoal briquettes. The equipment cuts quickly and neatly, and ultimately you will receive charcoal briquettes that are beautiful in appearance, easy to store and package, and can be sold in the market.