This sawdust briquette machine is one screw type extruder, which is a widely used equipment to compress biomass materials into briquettes with specific shapes. It is a very important machinery in sawdust charcoal briquettes production line. It can convert biomass waste (mainly wood waste) into valuable and profitable products.

Raw Material

- Wood and wood processing waste—firewood, wood pellets, and wood chips, wood shavings, lumber and furniture mill sawdust and waste

- Agricultural crops and waste materials—crop straw (corn stalk, soybean stalk, sorghum stalk, cotton stalk, rape stalk, peanut shell, sunflower stalk), chaff, grass, shrub branch, bamboo, coconut shell and bagasse

Beforing entering the sawdust briquette machine, the above biomass material should be preprocessed to meet the following requirements.

If your raw material is larger than 5mm, the wood sawdust crusher machine can be used to process the raw materials to required size.

As for humidity, there is a specialized sawdust dryer that can quickly reduce the moisture in the raw materials to the required humidity.

Only sawdust that meet the size and humidity requirements can produce the best briquettes.

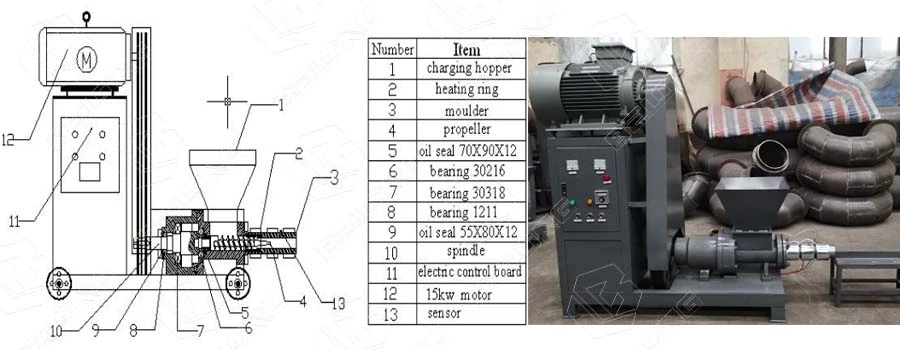

Basic Structure

The sawdust briquette extruder machine consists of a Feeding Hopper, Screw Propeller, Heating Coil, and Forming mold. The propeller rotates and compresses the biomass materials, forcing them through the forming mold to produce briquettes of various shapes and sizes.

Spare Parts

Screw Propeller

Heating Coil

Molds

Finished products

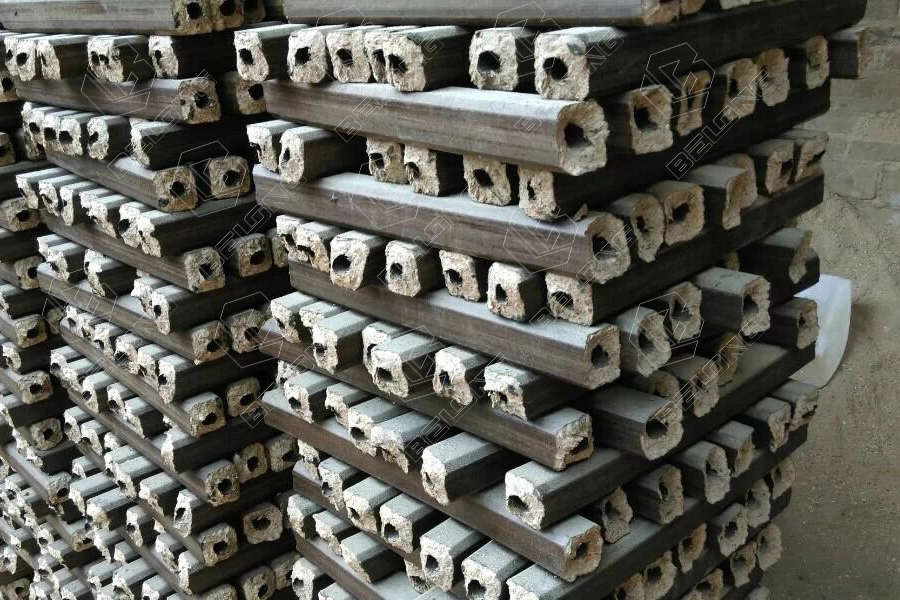

The finisded briquettes can be called machine-made wood briquettes, sawdust briquettes, and Biomass Briquettes, which is a biofuel substitute for traditional charcoal or coal and can be used for heating, cooking, and other industrial applications.

The finished square or hexagonal briquettes are typically hollow. Generally, the outer diameter range of the sawdust briquette is 50 to 80mm, the hole diameter range is 15 to 20mm.

hexagonal wood sawdust briquettes

square wood sawdust briquettes

Technical Parameter

| Model | Power | Capacity | Briquette diameter | Machine size |

|---|---|---|---|---|

| ZBJ-I | 18.5kW | 150-200kg/h | 50mm | 1500*600*1600mm |

| ZBJ-II | 22kW | 200-300kg/h | 50mm | 1700*700*1600mm |

| ZBJ-III | 30kW | 300-400kg/h | 70/80mm | 1850*700*1400mm |

Further Carbonization of Finished Briquettes

The finished biomass briquette is easy to ignite after carbonization, and they have a high calorific value (more than 20% higher than ordinary wood), fewer pollutants, and their specific gravity is convenient for storage and transportation, and can make full use of crop residues.

At Which Step in the Charcoal Briquettes Production Line Is the Briquette Machine Used: STEP 3

Step 1: Crush the wood material to certain size with a crusher

Step 2: Dry the wood sawdust to certain humidity with a dryer

STEP 3: Compress the wood sawdust to certain shape with a briquette machine

Step 4: Carbonize the sawdust briquettes to charcoal briquettes with a carbonization furnace