The briquette machine we will talk about here is the equipment that can compress various biomass materials into solid fuel blocks. And the final fuel briquettes can be of different shapes and for different use.

From the perspective of raw materials:

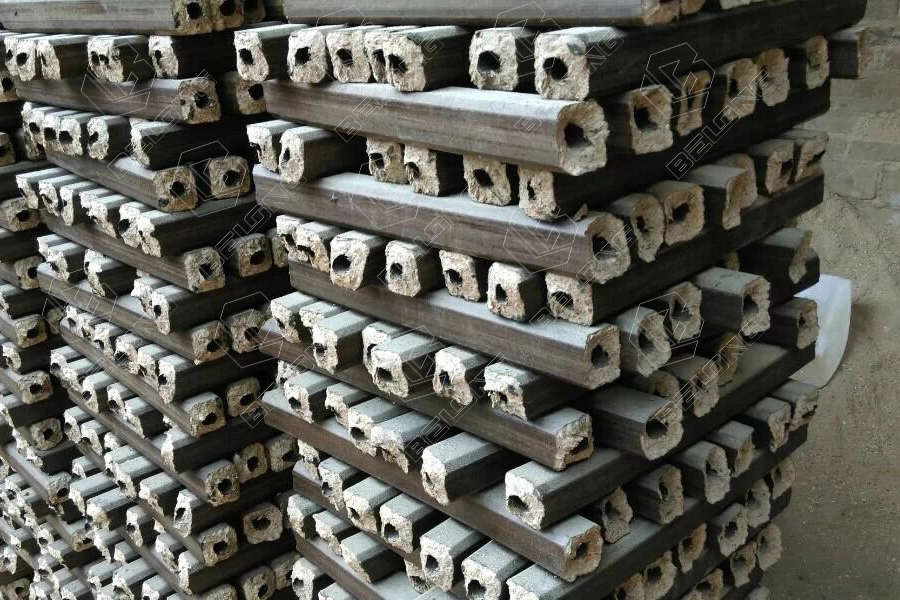

The screw type sawdust briquette machine uses various uncarbonized biomass waste as raw materials. It can extrude the biomass material into hollow rod-shaped briquettes.

There are several other types of briquette machine take charcoal/coal or carbonized biomass waste as raw materials. These machines usually make more shapes.

The raw material can be sawdust processed from wood and wood processing waste, and powdered agricultural waste. Its final products are square or hexagonal hollow briquettes, and generally, the outer diameter range of the sawdust briquette is 50 to 80mm, the hole diameter range is 15 to 20mm.

charcoal briquette extruder machine

Raw Material: This charcoal briquette machine is also called coal powder stick extruder. It can take coal powder, charcoal powder, semi coke and charcoal residue as the raw material.

Shapes Choice: The mold can be customized. By changing the mold, this charcoal briquette extruder can produce charcoal/coal rods of different shapes such as square, circular, and hexagonal.

Auxiliary Equipment: Charcoal crusher/grinder machine, roller grinding mixing machine, briquettes cutting device, conveyor