In this article, we will introduce the Biomass Briquettes. And what are the biomass briquettes used for? They are a biofuel substitute made made from biomass materials such as sawdust, wood waste, bark, rice husks, straw, and groundnut shells.

Application and Advantages of Biomass Briquettes

Application

Biomass briquettes can be used for heating, cooking fuel, and electricity generation. Due to its accessibility and eco-friendly impact, biomass briquette is very popular in some countries, which can be used to generate electricity through steam in heating boilers. It can provide more calorific value to save costs on boiler fuels.

Advantages

- Make Good Use of Waste Materials: Unlike firewood production, the production of biomass briquettes does not require the cutting of trees. On the contrary, they are usually made from agricultural waste or materials discarded during woodworking operations and sawmills. Taking this scrap material is much more cheaper than creating sawdust from firewood, achieving the effect of wood waste utilization.

- Eco-friendly: If poorly dried wood is used as fuel, it will release a large amount of harmful substances into the air. So, the lower the moisture content of biomass fuel, the less smoke it produces. Therefore, pollution will be reduced. Briquette has a higher energy density and is usually drier than firewood, which helps them burn cleaner and more efficiently.

The newly cut logs contain 50-70% moisture, while the moisture content of those waste materials after passing through our sawdust dryer (click the picture below to learn more) will be as low as about 10%, making the final briquette one of the cleanest biomass fuels.

- Easy to Store and Transport: Compressing biomass waste into briquettes reduces the volume by 10 times, making the storage and transportation of goods easier than that of loose biomass waste.

- Burn More Sufficiently:

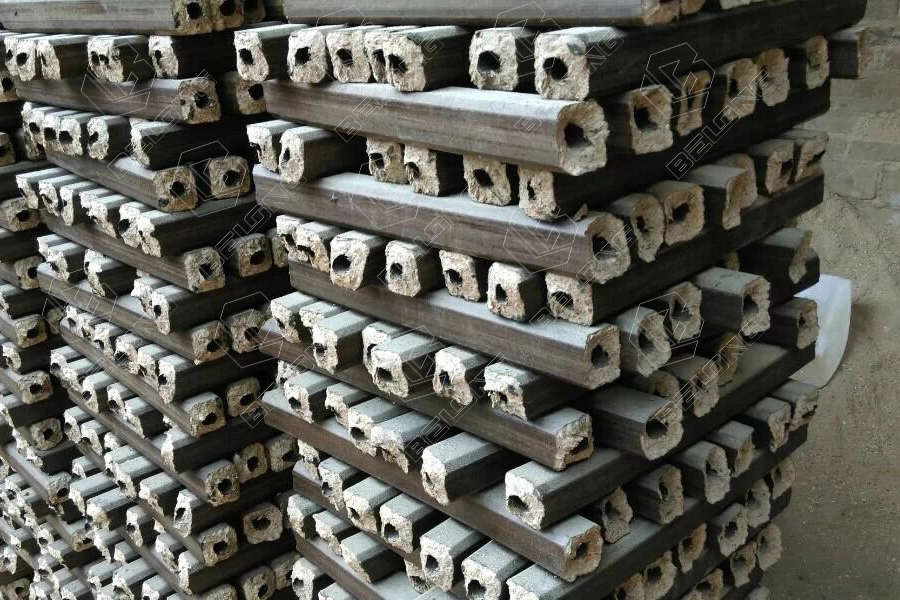

The biomass briquettes (on the right) made by our machine is mainly square or hexagonal shape with a hole through the center. The hole can increase the surface area of the briquettes and helps with efficient combustion. During the briquetting process, no binders are needed. The natural lignin in the wood binds the particles of wood together to form a solid.

Burning a wood briquette is far more efficient than burning firewood. The moisture content of a briquette is much lower than that of green firewood.

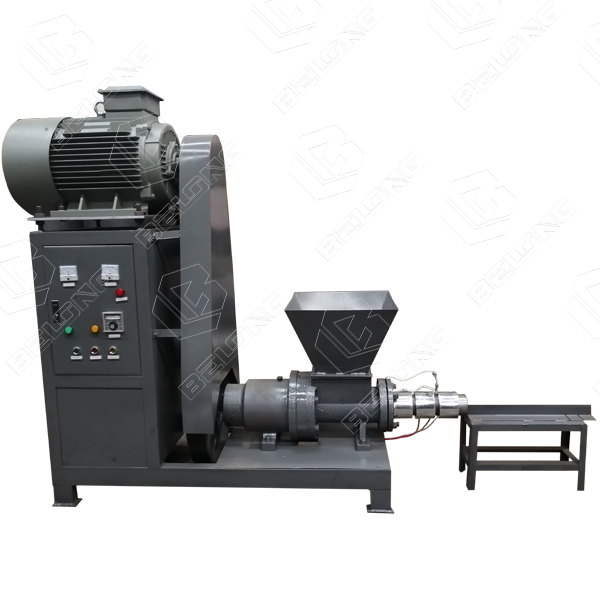

The briquette extruder consists of a feeding hopper, screw extruder, heating coil, and forming die. The screw extruder rotates and compresses the biomass materials, forcing them through the forming die to produce briquettes of required shapes and sizes.

| Model | Capacity |

|---|---|

| ZBJ-I | 150-200kg/h |

| ZBJ-II | 200-300kg/h |

| ZBJ-III | 300-400kg/h |

What Is the Difference Between Biomass Briquettes and Charcoal Briquettes?

| Briquettes Type | Biomass Briquettes | Charcoal Briquettes | Coal Briquettes |

|---|---|---|---|

| Raw Material | Wood,Wood waste (main source)

Agricultural waste (Peanut shell, Rice husk, Corn stalk, bagasse, etc); |

Charcoal powder from coconut shell, wood shavings, rice husk, peanut shell, bamboo, etc. | Coal Powder |

| Feature | Binder () | ||

| Briquettes Shape | Hexagonal/Square | Various molds | Various molds |

| Machine to Use | Wood Crusher/ | Carbonization Furnace/ |