Wood crusher machine is specially designed to crush wood materials, such as branches, tree roots, and slab scraps for further production. For example, in charcoal briquette production plants and wood pellet plants, wood crusher is usually used to produce high-quality sawdust. Due to its small footprint, wide range of uses, and adjustable size of finished wood products, it is quite popular in small-size biomass fuel briquettes production.

Besides, it is widely used in the preparation section and single sawdust processing of industrial production such as paper making, cultivation of edible fungi, charcoal production line, chipboard, sawdust board, high-density board and medium-density fiberboard.

Raw Material

The raw materials that can be processed by the wood crusher machine include bamboo, other wood materials (wood chips, sawdust, wood shavings, wood branches, wood logs, etc. ) and crop stalks and straws, etc.

The size range of the raw material that will enter the wood crusher machine should be between 1cm to 30cm.

Crushing Effect

After being crushed by a wood crusher, the size range of the raw materials is between 3-20mm.

And in the sawdust charcoal briquettes production line, the sawdust size required should be less than 5mm. By changing the screen mesh of the wood crusher, you can get the size you want.

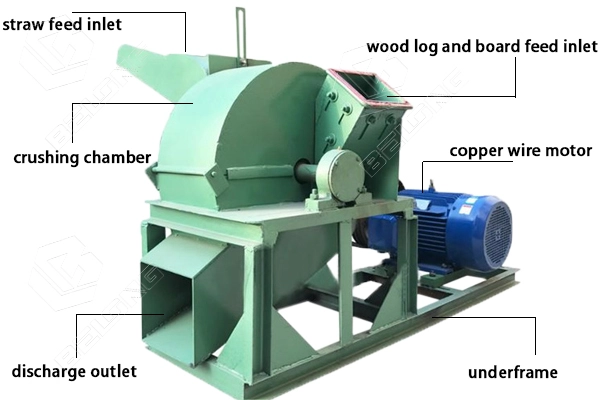

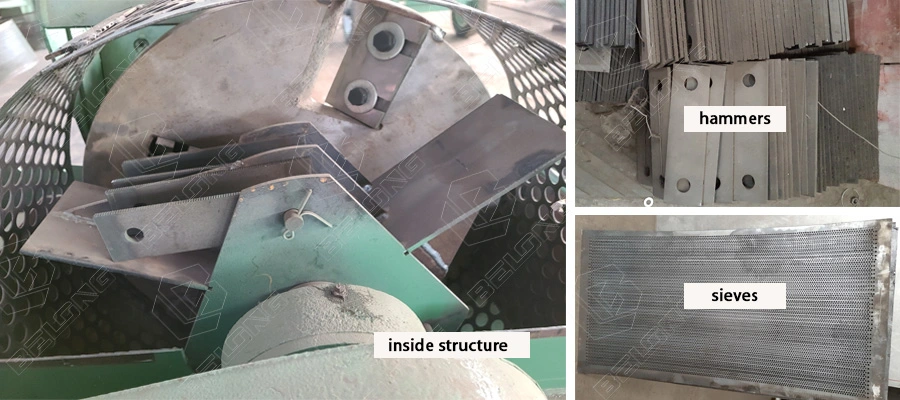

Basic Structure

The internal structure of the wood crusher machine is mainly composed of:

- the upper body

- the inner plate

- the cutter

- the lower body

- the rotor

- the blower

- the discharge pipe

- the underframe

- the bag dust collector

- and other parts

Technical Parameter

| Model | Power | Capacity | Blade disc diameter | Blade quantity | Blade size | Inlet size |

|---|---|---|---|---|---|---|

| 420 | 11kW | 1t/h | 420mm | 4pcs | 90*60*10mm | 18*15cm |

| 500 | 18.5kW | 1.5t/h | 500mm | 4pcs | 120*70*10mm | 20*18cm |

| 700 | 30kW | 2t/h | 600mm | 4pcs | 150*70*10mm | 23*20cm |

| 900 | 37kW | 2.5t/h | 610mm | 6pcs | 150*100*10mm | 24*20cm |

| 1000 | 55kW | 3t/h | 750mm | 8pcs | 150*140*10mm | 27*25cm |

| 1500 | 75kW | 4t/h | 750mm | 8pcs | 150*140*10mm | 28*26cm |

At Which Step in the Charcoal Briquettes Production Line Is the Crusher Used: STEP 1

STEP 1: Crush the wood material to certain size with a crusher

Step 2: Dry the wood sawdust to certain humidity with a dryer

Step 3: Compress the wood sawdust to certain shape with a briquette machine

Step 4: Carbonize the sawdust briquettes to charcoal briquettes with a carbonization furnace