How to make wood waste profitable is a good question that can help people start a business. Wood waste comes in huge quantities in wood processing and woodworking industry. Whether the wood is hard or soft solid wood, particle board or plywood, composite wood, OSB or MDF, wood waste will be generated. If we can view this wood waste as a raw material for another product, it will no longer be useless, but valuable!And wood briquettes is the product that can make waste profitable!

Here we will discuss how to make wood watse profitable with wood briquettes related machines.

Wood Briquettes Related Machines

The wood waste can come from the furniture industry as well as from sawmills and planning mills. Wood briquette machines can compress wood waste or byproducts into briquettes of different shapes and sizes, and these wood briquettes can be burned as fuel or sold for profit!

To make wood briquettes, generally, it requires 3 steps:

- Crush the wood materials to sawdust with a size of less than 5mm.

- Dry the sawdust to <15% humidity.

- Convert sawdust into sawdust briquettes

Next, we will introduce each machine in the above order one by one.

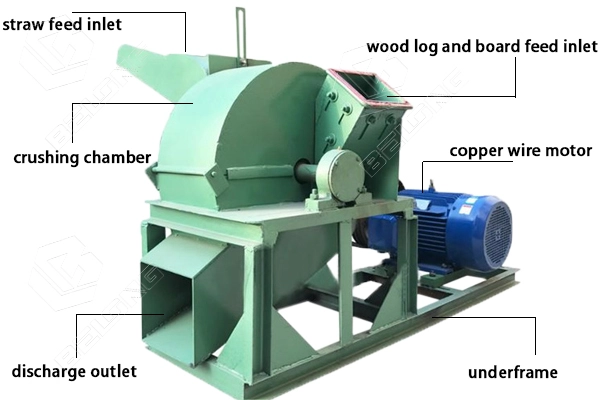

Wood Crusher Machine (for required size)

The required size for briquetting is less than 5mm. As we know, most wood waste has larger sizes and different shapes, such as wood shavings, wood chips, and wood scraps. So we need a crushing equipment to process the wood waste into sawdust smaller than 5mm.

Sawdust Dryer Machine (for required humidity)

Proper humidity has a significant impact on the briquetting process. If the humidity is too high, the sawdust will not form briquettes easily. The required humidity of wood waste for making wood briquettes should be controlled below 15%. After the crushing in the previous step, wood waste are turned into sawdust, making it easier to dry the raw materials to a certain humidity.

The picture on the left is air flow dryer. It is composed of a fan, a heating source, a drying pipe, and a cyclone separator. The sawdust or wood chips are fed into the drying pipe, where they are exposed to the hot air. The moisture evaporates and is carried away by air, while the dry material is discharged from the other end of the pipe. The cyclone separator is used to separate the dry material from the air and collect the dust.

In addition to the air flow dryer, there is also a rotary drum dryer that is more suitable for production lines with higher production demands.

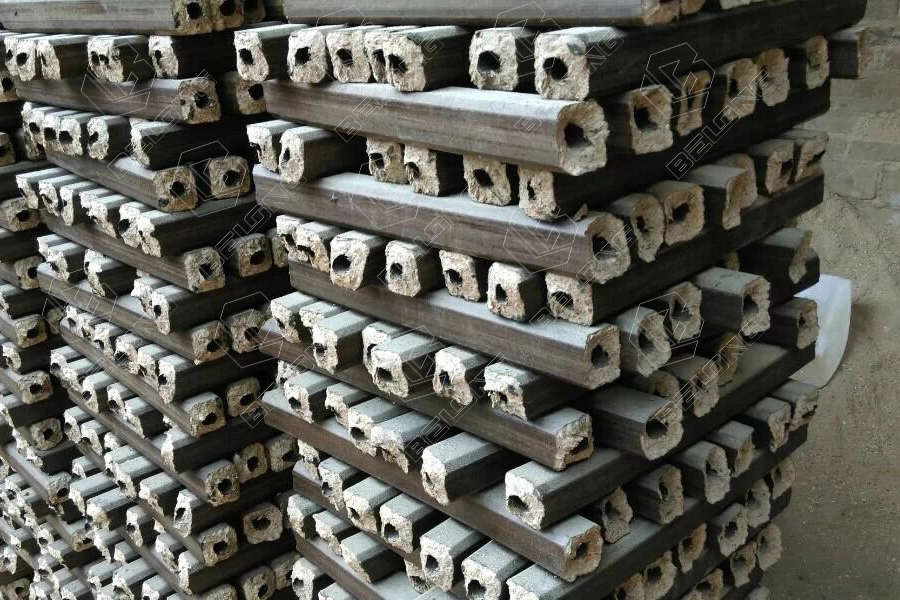

Briquette Machine (for required shape)

Now we come to the final step. After being crushed to a certain size and dried to a certain humidity, the wood waste is ready to be compressed to a certain shape briquette by machine. The finished products of the wood briquettes machine are typically hollow square or hexagonal briquettes. Generally, the outer diameter of the sawdust briquette is around 50mm.

The density of wood briquettes made by this machine is relatively high, and they can be used for daily-use heating, warming up greenhouses, or burning boilers.

Further Carbonization

If you want to make them more versatile, you can make them into charcoal. Making wood briquettes into charcoal only requires one step – carbonization. Carbonization only requires the addition of a carbonization furnace. If you do not want to purchase a carbonization furnace, you can also build your own earth kiln for charring, which is the original method. The carbonized sawdust briquette is smokeless and odorless, and has high heat value, and can endure burning for a long time.